August 19, 2025

Pierre Gonnetan, Arkema

Pierre Gonnetan leads Arkema’s global 3D printing business, focusing on high-performance thermoplastics including bio-based Rilsan® PA11, Orgasol® PA12, and Pebax® elastomers. A strong advocate for sustainability, performance, and innovation, Pierre and the Arkema 3D team have played a key role in building strategic partnerships and advancing additive manufacturing toward a more sustainable future.

Graduated in 2018 from École Polytechnique and holding an MBA from the Collège des Ingénieurs in Paris, Pierre gained international experience in materials R&D (Saint-Gobain, Germany) and renewable energy (Artelia, Vietnam) during his studies. He joined Arkema in 2019, initially working on ultra-high-performance materials such as Kepstan® PEKK before transitioning to the 3D printing division.

Pierre Gonnetan

How important is sustainability, environmental impact, and resource efficiency in your organization’s development or use of additive technologies? Explain a bit.

Pierre: Industry—and the chemicals industry in particular— generates innovations and offers solutions to the challenges of the environmental and energy transition. Innovation represents progress. It turns challenges into opportunities. 1

At Arkema, we can make a positive impact on today’s world through our innovations, our commitment to society and our technologies.

Our 1,800 researchers have embedded innovation in our DNA to drive our growth.

Every year, 90% of the patents we file are aimed at obtaining tangible benefits for sustainable development.

We invest heavily in groundbreaking solutions: bio-based and/or recyclable materials, materials for 3D printing, composites that reduce the weight of transportation, new-generation adhesives that make the components they bind recyclable, additives and resins that significantly improve the performance of materials and paints, and many other innovations that are essential for shaping tomorrow’s world.

Our product offer is accelerating our contribution to the UN Sustainable Development Goals (SDGs) with more efficient and sustainable materials. We expect to increase the proportion of our sales that make a significant contribution to SDGs from 53% today to 60% by 2030.

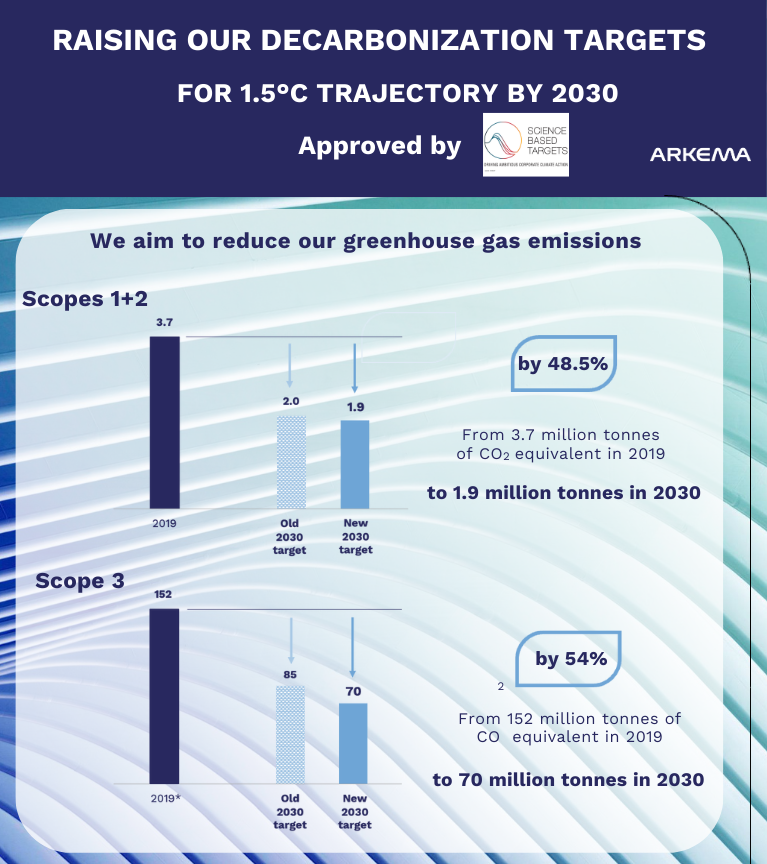

Arkema is also firmly committed to limiting global warming to 1.5°C by the end of the century, which requires drastically reducing anthropogenic greenhouse gas emissions and significantly decarbonizing the global economy. We have adopted one of the most ambitious climate plans in the chemicals industry. We set targets, validated by the Science Based Targets Initiative (SBTi) in 2023, to reduce greenhouse gas emissions from our plants and electricity purchases (scopes 1 and 2) by 48.5% by 2030 and emissions from our upstream and downstream activities (scope 3) by 54%, compared to 2019. These figures are calculated using the SBTi methodology and align with Arkema’s decarbonization trajectory, ensuring compatibility with the 1.5°C threshold regardless of growth. The 2030 targets pave the way for net zero by 2050, representing a 90% reduction in emissions across scopes 1, 2 and 3. 2

Our ambition for innovation is clear: to reduce the environmental impact of our plants and processes, of course, but also to use our materials to contribute to the transition to clean, carbon-free transport, more efficient renewable energies, sustainable low-emission construction, and cutting-edge electronics and manufactured goods that contribute to a more responsible economy. 3

Do your stakeholders, internal or external, view the economic and environmental impacts of additive technologies and strategies as being competing or complimentary?

Pierre: At Arkema, we view the economic and environmental impacts of additive manufacturing (AM) as complementary. The technology enables material efficiency, reduces waste, and supports localized production —lowering both costs and carbon footprint. New solutions like Orgasol® PA12 powders, reducing waste and lowering cost per part, illustrate this kind of approach. Our internal teams and external partners increasingly see sustainability and profitability as aligned goals, not trade-offs.

Do you have specific product offerings, use-cases, research, or initiatives with an emphasis on improved environmental outcomes that you are excited about?

Pierre: Arkema’s Rilsan® polyamide 11 is 100% bio-based from renewable feedstock castor seed. One project of note is the Pragati Sustainable Castor Initiative, which further drives for better practices, yield and community impacts around castor farming. For instance, water consumption is significantly reduced (over 30%) thanks to this program as compared to local averages. The project and the ongoing impacts are outlined in the following HERE.

Arkema is also offering new Orgasol® PA12 solutions, groundbreaking powders designed specifically for Powder Bed Fusion (PBF) technologies. In addition to its economic and aesthetic benefits, Orgasol® PA12 drives sustainability in 3D printing. The material supports a zero-waste solution thanks to the powder’s game-changing reusability, aligning with the growing demand for environmentally responsible manufacturing practices. Its recyclability ensures that waste is minimized, contributing to a more sustainable production process. You can learn more HERE.

How have you seen AM technologies and strategies used to produce better components, achieve greater resource efficiency, better manage inventories, and directly or indirectly improve environmental outcomes?

Pierre: AM has proven to be a powerful enabler of better component performance, resource efficiency, and environmental impact. For instance, in the aerospace sector, Arkema solutions are used to produce lightweight, topology-optimized parts that reduce fuel consumption and emissions. In the consumer goods space, Chanel’s 3D-printed mascara brushes made with Arkema’s PA11 demonstrated how AM can deliver high-performance, customized components at scale, while reducing material waste and inventory needs.

From a resource efficiency standpoint, AM allows for on-demand production, minimizing overproduction and warehousing. This is key for functional prototyping activities, that can be done on-site for large users in automotive for instance. It also supports digital inventories, where parts are stored as files and printed when needed—cutting down on logistics and associated emissions.

Environmentally, the use of bio-based materials like PA11, but also zero-waste solutions using Orgasol® PA12, further reduces the carbon footprint of final parts, aligning with circular economy principles. Overall, AM is not just a manufacturing method—it’s a strategic tool for sustainable innovation.

What is the most interesting use of additive technologies you have seen in the past year?

Pierre: One of the most fascinating applications of AM in the mass consumer market is Chanel’s industrial-scale production of mascara brushes using PA11. In collaboration with Erpro 3D Factory, Chanel has produced over 20 million units of the ‘Le Volume Révolution de Chanel’ brush using SLS (SLS) and Arkema’s bio-based PA11. This material was chosen for its flexibility, durability, and precision—essential for creating the brush’s unique micro-cavities and textured surface, which allow for optimal mascara loading and even application. The design, impossible to achieve with traditional molding, was iterated over 100 times to perfect lash separation and volume. This was not only a breakthrough in cosmetic performance but also a milestone in sustainable, high-volume additive manufacturing.

How important is collaboration (across business units, throughout the supply chain, with associations and academia) in pursuing sustainability initiatives? How have you or your organization collaborated for mutual benefit?

Pierre: Sustainability is indeed a collective journey. We need to inspire each other and to team up with stakeholders to address the multi-dimensional challenges over the entire lifecycle of products.

For example, at the very beginning of the value chain of our Rilsan® PA11, we support the Pragati initiative that was launched in 2016 together with BASF, Jayant Agro-Organics, and Solidaridad provides educational materials to improve the skills and knowledge of the local farmers, to improve their income, and to ensure better health and living conditions.

At the end-of-life , our Virtucycle® program is a partnership program offered to Arkema’s high-performance polymers customers and downstream users. The program enables our partners to “step into the loop” by providing polymer for reprocessing or to source new materials with minimum recycled content and no compromise in performance. In 2024, this program has been launched at EOS and HP and its benefits in terms of CO2 emissions quantified and independently verified. Learn more HERE.

Why is sustainability important to you personally? Do you have specific activities or experiences that you consider when thinking of environmental impacts?

Pierre: Sustainability is important to me because I believe innovation should benefit both people and the planet. I try to be mindful of the environmental impact of everyday actions—whether it’s making thoughtful travel choices or adopting more sustainable eating habits. Seeing how technologies like 3D printing with bio-based materials such as PA11 and PA12 can reduce waste and emissions makes sustainability feel real and actionable in my professional life.

1 TLH INNOVATIVE 2024

2 EB INNOVATIVE 2024

3 TLH INNOVATIVE 2024

The claims and views expressed in this Member Spotlight Interview are not necessarily those of the AMGTA, its staff, its Board of Directors, or member organizations. The AMGTA is not responsible for the content or accuracy of any information or claims provided as part of this Member Spotlight Interview and shall not be responsible for any decisions made based on such information.