By AMGTA

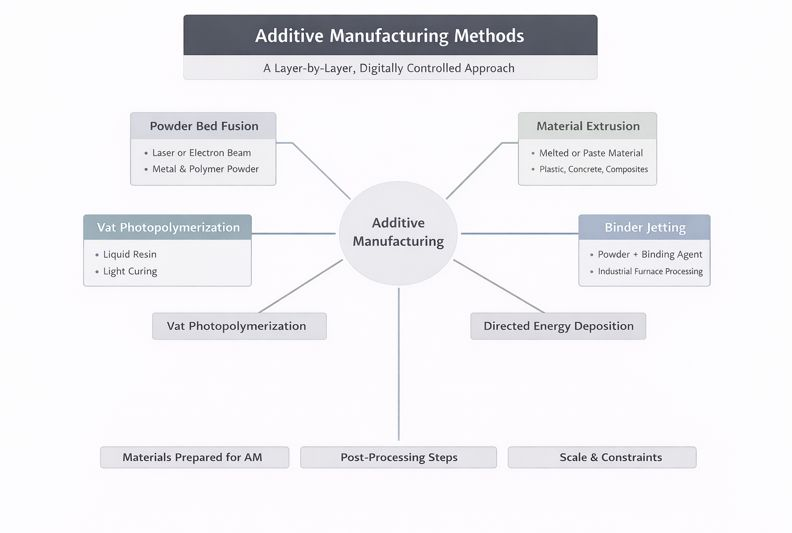

Additive manufacturing, a wide array of technologies centered on “3D printing,” is not a single technology. It is a family of manufacturing methods that share one defining characteristic: parts are built layer by layer, directly from digital data, rather than being cut, molded, or formed from bulk material.

This layer-by-layer approach enables shapes, structures, and production pathways that are difficult or impossible with traditional methods. It also introduces distinct constraints related to materials, process control, post-processing, and qualification. Understanding additive manufacturing therefore begins with understanding how layers are created and bonded, rather than focusing on individual machines or brands.

This overview is intended to provide high-level technical orientation for readers who want to understand how additive manufacturing works, without turning into a process manual or implementation guide. It operates at the technical-method level, not at the level of qualification, certification, or application-specific performance, which are addressed elsewhere.

Additive vs. Subtractive Manufacturing

Traditional manufacturing methods typically shape parts by removing material from a larger block, forming material into molds, or deforming it into fixed shapes. Additive manufacturing works differently. Parts are created by adding material only where it is needed, layer by layer, directly from digital data.

This structural difference—adding material incrementally rather than removing or forming it—underlies many of additive manufacturing’s distinctive capabilities and constraints. It explains why geometry, internal structures, and commitment timing behave differently in additive processes than in conventional manufacturing, even before material or performance considerations are introduced.

Powder Bed Fusion: Fusing Powder with Energy

One of the most widely used additive manufacturing approaches is powder bed fusion.

In this method, a thin layer of powder—metal or polymer—is spread across a build surface. A focused energy source, most commonly a laser, selectively fuses regions of the powder based on a digital design. Once a layer is complete, a new layer of powder is spread, and the process repeats. Over time, a three-dimensional part is formed within the powder bed.

Unfused powder surrounding the part provides support during the build, enabling complex internal geometries and certain overhangs without separate tooling.

Powder bed fusion is commonly selected when organizations need:

- Complex geometry (including internal features)

- Repeatable, tightly controlled processing

- Material properties appropriate for demanding applications

It is also constrained by:

- Enclosed build chamber size

- Requirements for controlled build conditions

- Post-processing to remove powder and achieve final surface/fit requirements

Material Extrusion: Depositing Material Layer by Layer

Another major category of additive manufacturing is material extrusion.

In extrusion-based systems, material is pushed through a nozzle and deposited in layers according to digital instructions. The material may be melted, softened, or delivered as a paste or solution, depending on the application.

For polymers, this often involves heating solid material until it can be deposited and solidified. In other contexts, extrusion systems deposit materials such as composites, pastes, or construction-grade compounds that harden after deposition.

Material extrusion systems vary widely in scale. Some are small and enclosed; others operate without fixed build chambers and are limited primarily by machine reach and stability rather than enclosure size.

Tradeoffs typically include:

- Lower resolution compared to powder bed systems

- Greater dependence on material behavior during deposition

- The need for support strategies in certain geometries

Directed Energy Deposition and Hybrid Systems

Some additive manufacturing systems deliver material directly into a focused energy source, depositing metal wire or powder as it is fused in place. These approaches are often used for larger components, repair, or hybrid manufacturing environments where additive and subtractive processes are combined.

While the physics and scale differ from powder bed systems, the underlying logic—digitally controlled, layer-wise material addition—remains the same.

In many industrial settings, additive manufacturing is not a standalone process but part of a hybrid workflow, combined with machining, inspection, or finishing operations.

Binder Jetting: Shaping First, Strengthening Later

Binder jetting takes a different approach.

Instead of fusing material during the build, thin layers of powder are spread and selectively bound using a liquid binding agent. The printed part, often referred to as a “green” part, has shape but limited strength.

After printing, parts undergo further processing—often in an industrial furnace—where material properties are developed through heat and time.

Binder jetting is often valued for:

- Efficient production of multiple parts in a single build

- Separation of shape creation from material densification

- Applicability to metals, ceramics, and other powders

Final properties depend heavily on post-processing and process control rather than the printing step alone.

Vat Photopolymerization (Resin-Based Methods)

Some additive manufacturing methods build parts by selectively curing liquid materials using light. These approaches are commonly used for high-resolution polymer parts, tooling, and patterns.

While the materials and physics differ from powder-based or extrusion methods, the core principle remains the same: solidifying material layer by layer from digital data.

Materials as Engineered Inputs

Across additive manufacturing methods, materials are not simply off-the-shelf forms.

Many additive processes rely on materials that are prepared specifically for the method being used. Metals, for example, are often converted into powders with controlled size and flow characteristics. Polymers may be formulated as filaments, powders, or liquids depending on the process.

These material forms are engineered inputs, not incidental choices. They influence process behavior, part quality, post-processing requirements, and qualification pathways.

Printing Is Only Part of the Process

Across nearly all additive manufacturing methods, the printed part is not the finished part.

Heat treatment, curing, sintering, surface finishing, machining, and inspection are often required to achieve final properties and tolerances. These steps are integral to how additive manufacturing functions in practice. The presence of post-processing does not diminish the additive nature of the process; it reflects the separation between building geometry and achieving performance.

Size, Scale, and Constraints

Additive manufacturing methods differ significantly in how size is constrained.

Some processes are limited by enclosed build chambers. Others operate with minimal enclosure and can produce very large parts or structures. These differences affect not only what can be built, but how parts are segmented, assembled, and deployed.

Boundary Conditions and Technical Rigor

In regulated or high-performance environments, additive manufacturing must meet qualification, certification, and standards requirements that vary by application and industry. These considerations are real and consequential, but they are independent of the underlying method by which layers are created.

This overview does not attempt to resolve those technical boundary conditions. It assumes that material performance, process control, qualification, and certification remain essential and are addressed through established technical pathways.

A Family of Methods, Not a Single Technology

The most important takeaway is that additive manufacturing is not one process, one material, or one scale.

It is a family of technologies unified by a layer-wise, digitally controlled approach to building parts, but differentiated by how material is delivered, bonded, and finished.

This technical diversity helps explain both the promise and the complexity of additive manufacturing—and why discussions of strategic impact must clearly distinguish between technical feasibility and organizational interpretation, as outlined in the accompanying materials (link to Technical Boundary Overview)