April 1, 2025 4 min read

What are 3D-Printing and Additive Manufacturing?

Authored by AMGTA Executive Director, Sherri Monroe

A quiet revolution is reshaping how we design, make, and deliver products. Much like the assembly line transformed mass production or e-commerce redefined retail, additive manufacturing is fundamentally altering product development, supply chains, and resource strategies—with profound economic and environmental implications.

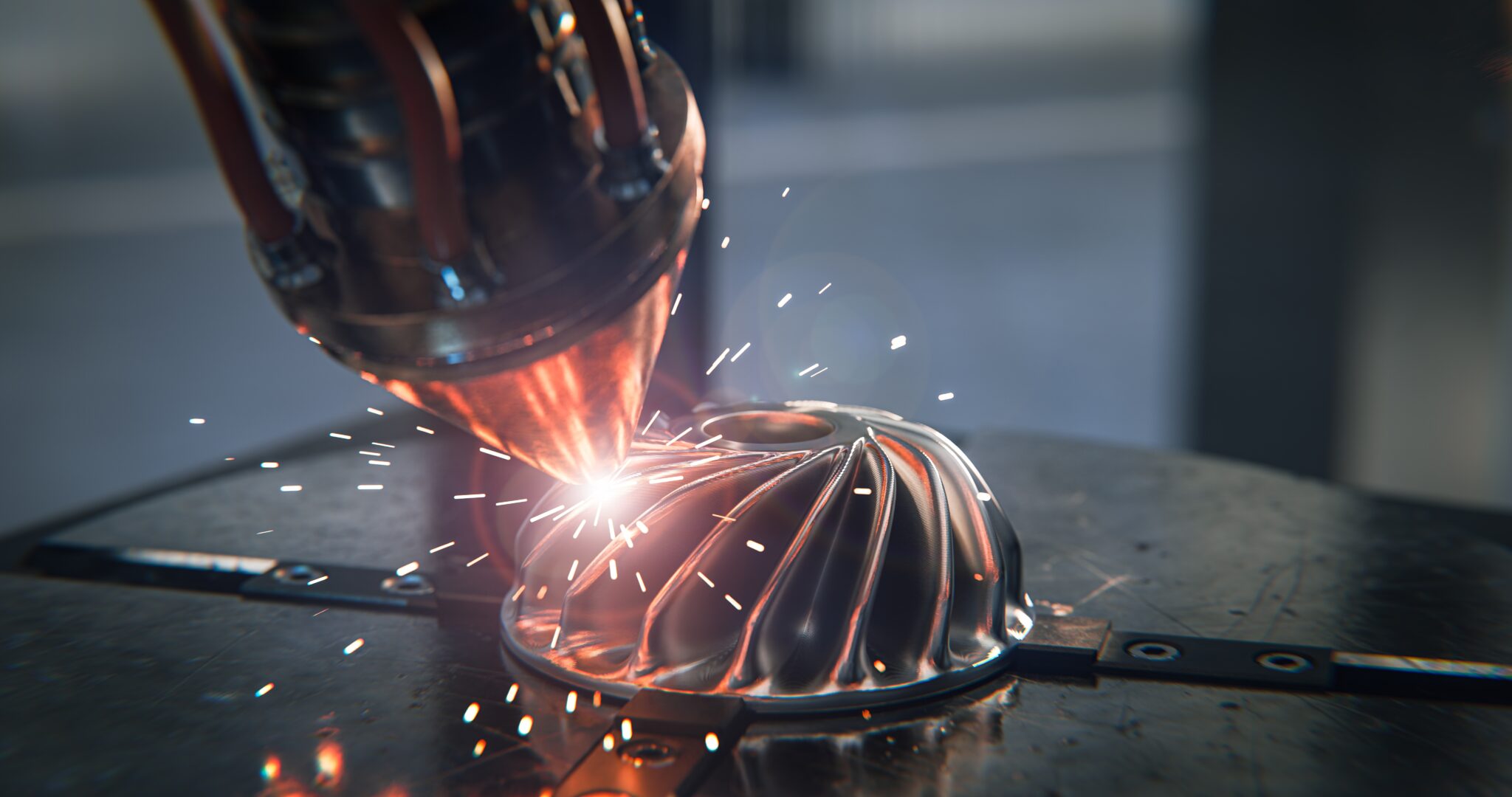

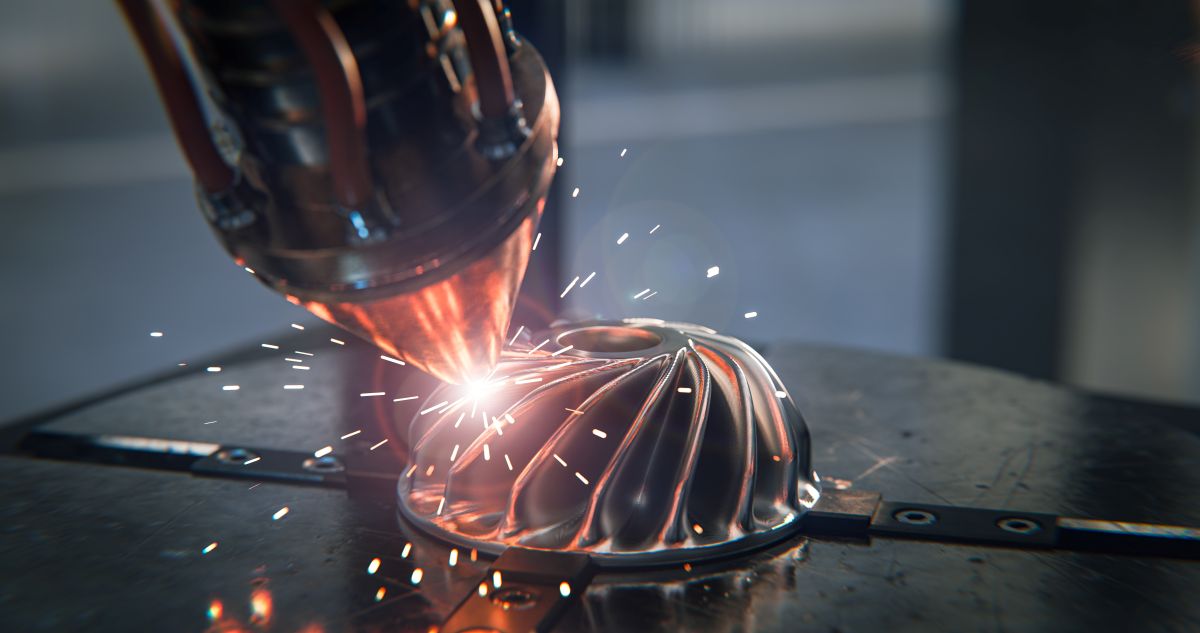

3D-Printing and the Rise of Additive Manufacturing

Often used interchangeably, “3D-printing” and “additive manufacturing” (AM) refer to related but distinct ideas. 3D-printing describes the physical process of building objects layer by layer—initially resembling an inkjet printer with added dimensions. AM, on the other hand, is the broader term that encompasses these technologies and the strategic advantages they enable, including design freedom, resource efficiency, and distributed production.

The COVID-19 pandemic, geopolitical disruptions, tariffs and market shifts, and logistical bottlenecks have exposed vulnerabilities in global supply chains. In response, companies are increasingly turning to additive manufacturing to produce everything from face shields for hospitals to spare parts on the battlefield to back-ordered parts holding up production lines to fulfilling volume production demands. These real-world deployments highlight AM’s potential to deliver time-sensitive solutions while reducing both environmental and economic cost.

3D-printing and additive manufacturing (AM) refer to related but distinct ideas.

3D-printing: The physical process of building objects layer by layer

Additive manufacturing: The broader set of technologies and production strategies enabled by 3D-printing, including design freedom, light-weighting, part consolidation and the unique geometries possible only through layered printing.

Beyond the Hype

While 3D-printing has been around for more than 20 years, it has largely been relegated to rapid prototyping and very specific customized applications. That is changing. AM is increasingly a powerful force in commercial operations and serial, volume production.

Like many technologies the initial hype around 3D-printing got a bit ahead of its skis very similar to the current discussions around artificial intelligence (AI). That doesn’t mean the skis aren’t real and the hype isn’t valid.

Beyond Prototypes: The Maturing of AM Technologies

AM technologies and strategies are meeting the moment as a viable option for commercial production. Today’s additive manufacturing includes technologies such as:

• Fused filament fabrication for plastic components

• Laser powder bed fusion (LPBF) for high-strength metal parts

• Binder jetting for complex shapes using powdered materials

• Vat photopolymerization and metal solution deposition for detailed and specialized parts

These and numerous other techniques build up rather than cut away material—hence the term “additive.” This approach unlocks entirely new capabilities, such as printing closed internal chambers, curved channels, and complex geometries that traditional methods like casting or machining simply can’t produce without assembly.

Printable materials include metals, plastics, resins, ceramics, and concrete.

Traditional manufacturing methods have long defined what was possible.

Additive manufacturing removes many of those constraints resulting in:

• Consolidated parts

• Reduced tooling

• Shortened development timelines

• Lower shipping and material costs

• Faster time-to-market

Why This Matters for Business Strategy

Traditional manufacturing constraints have quietly shaped how we design and build. Additive manufacturing breaks these constraints, allowing engineers to consolidate parts, reduce tooling, and shrink development timelines. The result? Products that use fewer materials, weigh less, perform better, and are cheaper to ship—all while being faster to market.

If your business is focused on cost savings, consider this: nearly every dollar saved—except perhaps in labor—also represents a gain in energy or material efficiency. Less energy used, less waste produced, and less material consumed all point toward both economic and environmental improvements. The idea that sustainability must come at the cost of profitability is increasingly outdated.

Looking Ahead

We are at a tipping point. Additive manufacturing is no longer just about novel techniques; it’s about redefining what’s possible in business. From part consolidation to local production, AM is enabling new strategies that enhance resilience, sustainability, and competitiveness.

In future posts, we’ll explore additive value strategies—how leading companies are building competitive advantage by integrating 3D-printing and AM into core business models. These strategies go beyond production methods to transform how companies think about innovation, efficiency, and long-term growth.

Stay tuned as we dive deeper into the future of manufacturing—and the value that’s being added layer by layer.